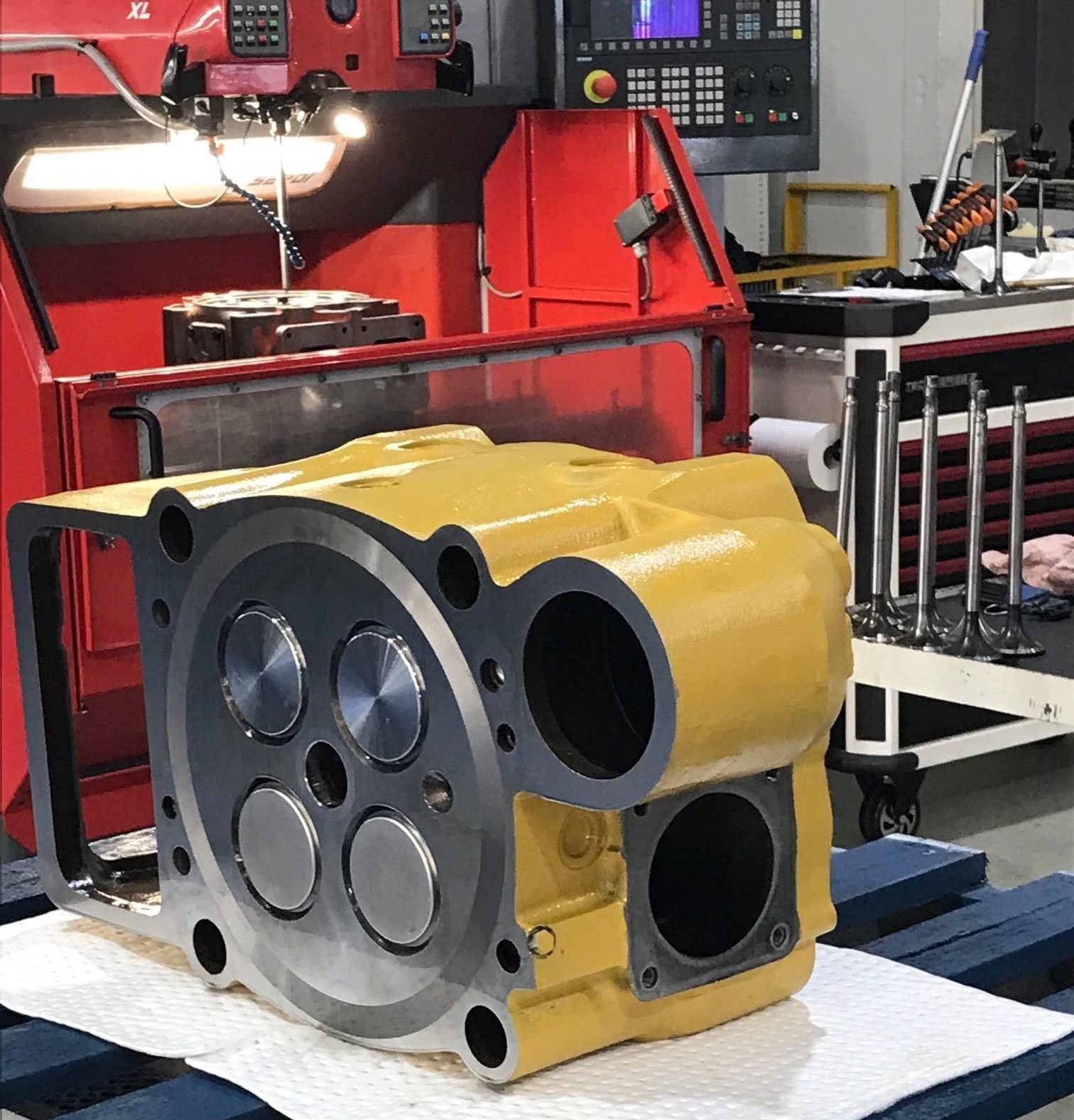

The sophisticated machine tools at Teterin Engineering have again proven their worth this time with the machining and reconditioning, to ‘zero-hour’ standards, of large cylinder heads for Australia’s gas industry.

Not so long ago, if a large cylinder head from one of Caterpillar’s largest gas compression engine models, the 3600 series, was to be reconditioned to zero-hour standards, it would have been returned to Caterpillar in the USA. But not anymore.

With Teterin’s CNC machining centre, the first of its type in the world, large cylinder heads like the CAT 3600 heads, can now be fully machined and reconditioned to zero-hour standards without the cylinder heads having to leave the country to be reconditioned.

Teterin recently completed a set of CAT 3600 heads used in the gas industry. The cylinder heads were fully reconditioned to zero-hour standards and valve seats machined by the CNC machining centre to the highest dimensional accuracy, perfect concentricity and the finest surface finish possible. The cylinder heads were then vacuum tested. The vacuum pressures recorded were consistently 30% higher than the average vacuum pressure test results for other cylinder heads.

.

.

This was an outstanding result, only achieved because of the advanced CNC machine tools and the skill and experience of Teterin technicians. The superior valve sealing will result in longer operational life for these cylinder heads.

“These CAT 3600 heads are the first of their type to be reconditioned on a CNC machining centre in Australia. The benefit of reconditioning these large CAT heads at Teterin is immediately apparent when we can achieve such remarkable zero-hour rebuild outcomes. The work we have done is going to extend the operational life of the cylinder heads, improve operational reliability and lower the cost of ownership for the gas producer. Its very pleasing for Teterin, through its investment in the latest machinery, its skilled and experienced technicians, to make such a contribution to the success of its customers and Australia’s gas industry.”

Peter Burgess – Managing Director, Teterin Engineering

Teterin Engineering has the latest machinery with the largest capacity in Australia to recondition and rebuild all large slow, medium and high-speed industrial engines. The company continues to break new ground and set new standards of excellence through its investment in machine tools and skilled technicians for the benefit of its customers in the mining, gas, marine, rail and defence industries.

.