Industry-Leading Expertise

Through a joint venture between Teterin and Germany’s August Storm GmbH & Co. KG, we formed Cirrus Power Systems as a gas engine specialist. The JV combines 150 years’ experience and some of the most highly skilled engineers and world-class equipment in this field globally.

In conjunction with Cirrus, Teterin services the Gas Industry of Australia and its neighbours, including Papua New Guinea and New Zealand, for:

- Quality component reconditioning

- Gas engine rebuilds

- In-situ machining, on-site overhauls and other field service

- Upgrades and retrofitting of engine management systems

- Service exchange gas engines and components

- Spare parts, warehoused in Australia for fast delivery.

Our customers include gas industry service companies, engine package distributors, power generation companies using natural gas, coal seam gas (CSG), landfill gas and biogas.

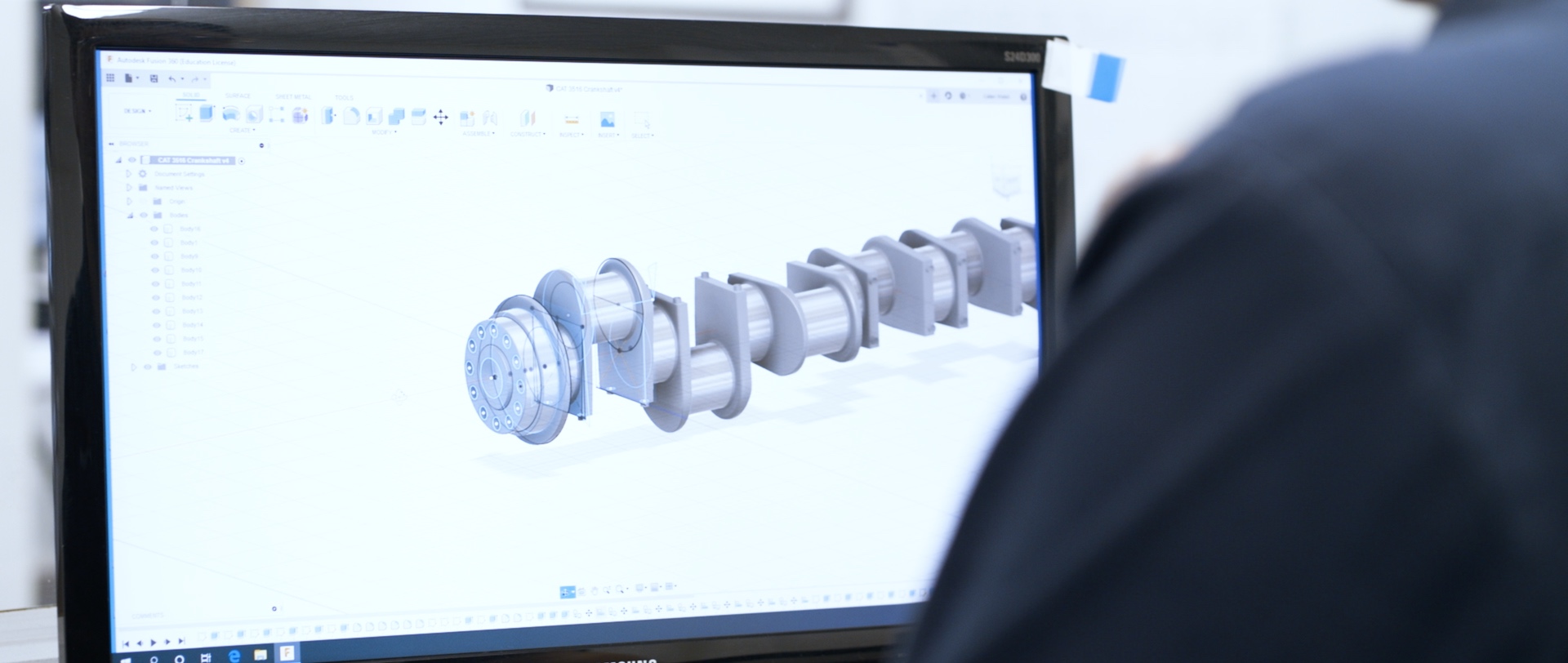

Extensive Workshop Capacity

Teterin’s engineering facility is equipped to machine all sizes and types of engine blocks, crankshafts and cylinder heads used in the Gas Industry. We recondition and rebuild all major gas engines, gas compression engines and stationary generators, including Jenbacher, MWM / Deutz, MAN, MTU, Cat, Cummins and Waukesha.

View our Capability & Capacity Statement

Proven Reliability, Faster Turnaround

Our Quality Management System is certified to ISO 9001:2015 ensure a consistently precise standard of work, which translates to greater engine reliability, longer service intervals, lower through-life operating costs and better value for money.

Recent significant investment in programmable CNC crankshaft grinding and valve seat machining centres has also enhanced our ability to deliver repeatable precision and faster turnaround time. For instance, our CNC crankshaft grinder – the only one of its kind in Australia – allows us to quickly grind every journal to very high levels of repeatable accuracy. This investment in our machining capability, together with our industry-leading ERP System and integrated Quality Management System, enables us to perform at world-class standards, to minimise your downtime and maximise your profitability.

World-Class Equipment, Quality Assured

Click below for more information on our latest cutting edge equipment, and our Quality Management System and workshop accreditation.

Programmable CNC Crankshaft Grinder

- First of its kind in Australia – no other crankshaft grinder in the Southern Hemisphere has this machine's capability

- Computer numeric controlled system enables the ultimate in repeatable precision

- Grinding time can be reduced over traditional manually operated equipment

- 12,000mm bed length accommodates crankshafts and other shafts up to 4,600mm

- Multi-function sensor systems include wheel balancing, in-process measuring, gap control

- Ideal for crankshafts from large industrial engines, including Cat 3600, MTU 4000, Waukesha 7042/7044 and AT, Cummins QSK, Jenbacher 6 Series, White Superior, MWM 2020, ALCO and EMD.

CNC Valve Seat Machining Centre

- Most technically advanced machine of its type in the world

- Computer numeric controlled system automates cylinder head machining with repeatable precision

- Up to 8 cylinder heads can be machined at once, reducing machining time

- Accommodates large cylinder heads up to 350kgs each

- Fully programmable multi-angle valve seat, single point cutting for fast turnaround & excellent finish

- Ideal for reconditioning cylinder heads in gas power generation engines, amongst others.

Fixed Bridge CMM (Coordinate Measuring Machine)

- Discovery II D-28

- Far superior precision measuring than with a typical CMM arm, removing any variability

- Accuracy of measurement and reporting essential for critical and complex components

- Ideal for servicing our partners in the Defence Industry and Alternative Energy.

ISO 9001:2015 Quality Managements System

Certified to ISO 9001:2015 by Lloyds Register Quality Assurance

ISO 9001 is the internationally recognised quality management system standard, and the preferred solution for over half a million organisations in 159 countries.

ISO 9001 is the internationally recognised quality management system standard, and the preferred solution for over half a million organisations in 159 countries.

Teterin’s Quality Management System is fully integrated with our own Integrated Management System (IMS) and ERP System. The IMS System incorporates the company’s safety and environment management systems, and together with the Quality Management System, provides a complete and highly effective management system.

Teterin has been certified to ISO 9001:2015 since 1995.

NATA Accreditation for ExDES

Certified NATA Accredited Workshop for Explosion Protected Diesel Engine Systems

Teterin is a Certified NATA Accredited engineering facility for diesel engines which operate in explosive atmospheres underground. Teterin was one of the first companies to become accredited for Explosion Protected Diesel Engine Systems (ExDES).

Teterin is a Certified NATA Accredited engineering facility for diesel engines which operate in explosive atmospheres underground. Teterin was one of the first companies to become accredited for Explosion Protected Diesel Engine Systems (ExDES).

NATA is the authority that provides independent assurance of technical competence through a proven network of best practice industry experts for customers who require confidence in the delivery of their products and services.

Teterin has been NATA-accredited since 2012.